Treatment of water and liquids with the Flocazur technology

The Uniqueness of Flocazur

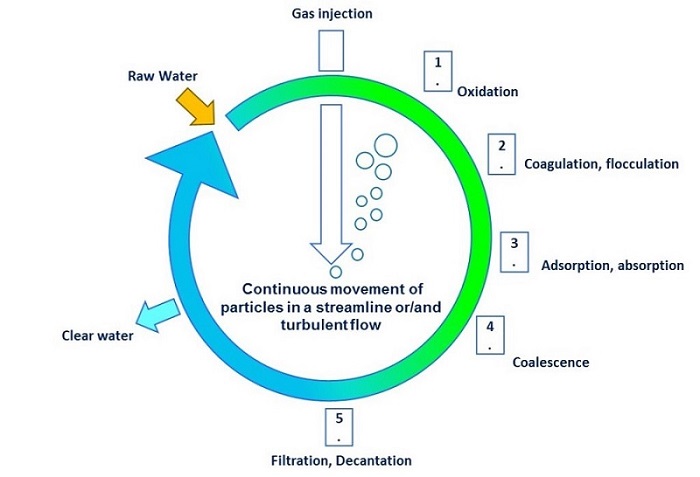

Flocazur is a technique that consists of only one step – five different reactions in one reactor.The Flocazur technique could constitute a whole treatment installation or be part of a separation treatment system.The Flocazur technology uses and enhances the natural physical and chemical forces that bind particles. These forces are Brownian diffusion and Van der Waals attraction with strong adsorption/absorption and coagulation/flocculation capacity. These reactions together form a coalescence – the formation of homogenised sludge. The Flocazur reactor is designed to be fast and effective as to maximize coalescence in order to obtain homogenised sludge that is easy to separate. This makes it possible to use very small quantities of chemical polymers or avoide the use entirely. The Flocazur reactor also constitutes a very several effective transformation processes – nitrification, denitrification and separation of phosphor.

Patented Technology in Sweden, USA, China, South Africa, Australia, Brazil, Russia, France, England and Germany.

Technical Advantages

Works on many liquids over wide ranges of densities and viscosities

Works over a wide range of temperatures

Optimizes pH and alkalinity management

Increases oxygen level and redox potential

Optimizes the reaction time for adsorption, absorption, coagulation and flocculation

Works with particles of different volumes and mass

Effectively reduces suspended solids, hydrocarbons, nitrogen and phosphor

Optimizes sludge thickening and coalescence

Optimizes the production of sludge, both in quality and quantity

Effectively reduces chemical oxygen demand (COD), biological oxygen demand (BOD) and total organic carbon (TOC)

Optimizes biological capacity for nitrification and denitrification

Efficient skimming of seawater

Reduces energy consumption

Reduces the use of chemicals

Is scalable and can be included in another clarification process or perform on its own

By means of

New innovative reactor design

New innovative blending technique

Optimization of chemical reactivity

Effective stripping of harmful gases

Effective dispersion of hydraulic energy in the reactor between processes

Optimization of oxidation by a more efficient diffusion technique of air or ozone

Optimization of the particle interaction rate in the reactor / coagulation

Optimization of flocculation by efficient energy transfer after coagulation

Optimization of growth and bacteriological reactivity with or without natural carriers

Perfectly suited for MBR, MBBR, GSBR and GSBBR bed systems

Longer Hydraulic Retention Time (HRT) in the reactor

Simultaneous management of flotation and settling